LNG to CNG Conversion for New Generation Engines

Tecnocryo: FGSS Systems for ME-GI Ships

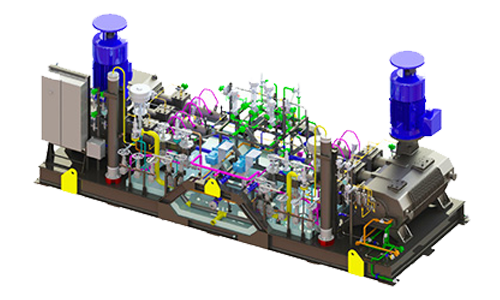

Tecnocryo designs and manufactures Gas Supply Systems (FGSS) to convert LNG into CNG for new generation ME-GI engines for ships.

These systems are designed to be built according to the customer’s specifications. The partnership with Tecnocryo guarantees:

- Complete mechanical design and engineering

- Definition of equipment

- All-in-One Skid Modules

- Product Reliability and Quality

The feeding systems designed by Tecnocryo are:

High-pressure LNG pump skids (ME-GI type skid)

Double and Single Cryogenic Pump Skids

SPECIFICATIONS:

Complete Mechanical Design

Compactness

Extended Service Life

Reliability and Quality

Rules for Ships of Any Class or Register

QUALITY:

- Design and Production

- Installation and Assembly

- Testing and Inspection

- All carried out at Tecnocryo facilities

- Skids delivered with Class certification for installation on ships

Skids with double Cryogenic pump

TECHNICAL SPECIFICATIONS:

Type: LNG

Flow: up to 6200 kg/h (per pump)

Pressure: up to 370 barg

Temperature: -196°C / +65°C

Power: less than 200 kW (per pump)

Pump Speed: less than 340 rpm for long life

Hydraulic Efficiency: above 85%

Transmission: Lubricated gearbox for long life

Single Cryogenic Pump Skid

TECHNICAL SPECIFICATIONS:

Type: LNG

Flow: up to 1900 kg/h (per pump)

Pressure: up to 420 barg

Temperature: -196°C / +65°C

Power: less than 90 kW (per pump)

Pump Speed: less than 450 rpm

Hydraulic Efficiency: above 85%

Transmission: Pulley with toothed belts for easy maintenance

LNG VAPORIZATION SKID (HTF TYPE)

SPECIFICATIONS:

Compactness

Extended Service Life

Reliability and Quality

Rules for Ships of Any Class or Register

QUALITY :

- Design and Production

- Installation and Assembly

- Testing and Inspection

- All carried out at Tecnocryo facilities

- Skids delivered with Class certification for installation on ships

LNG Vaporization Skid (HTF)

TECHNICAL SPECIFICATIONS:

Type: LNG to CNG; glycol-water circuit for LNG vaporization; hot water as a heat source

LNG Flow: up to 6200 kg/h

Glycol-water: from 60 to 130 m3/h depending on the temperature difference

Hot Water: from 40 to 60 m3/h depending on the temperature difference

Pressure: designed for 10 barg for glycol-water and hot water

Temperature: between 55°C and 80°C

Power: less than 20 kW (per pump)

Overall Dimensions: 3 m x 3.5 m, height 3.2 m